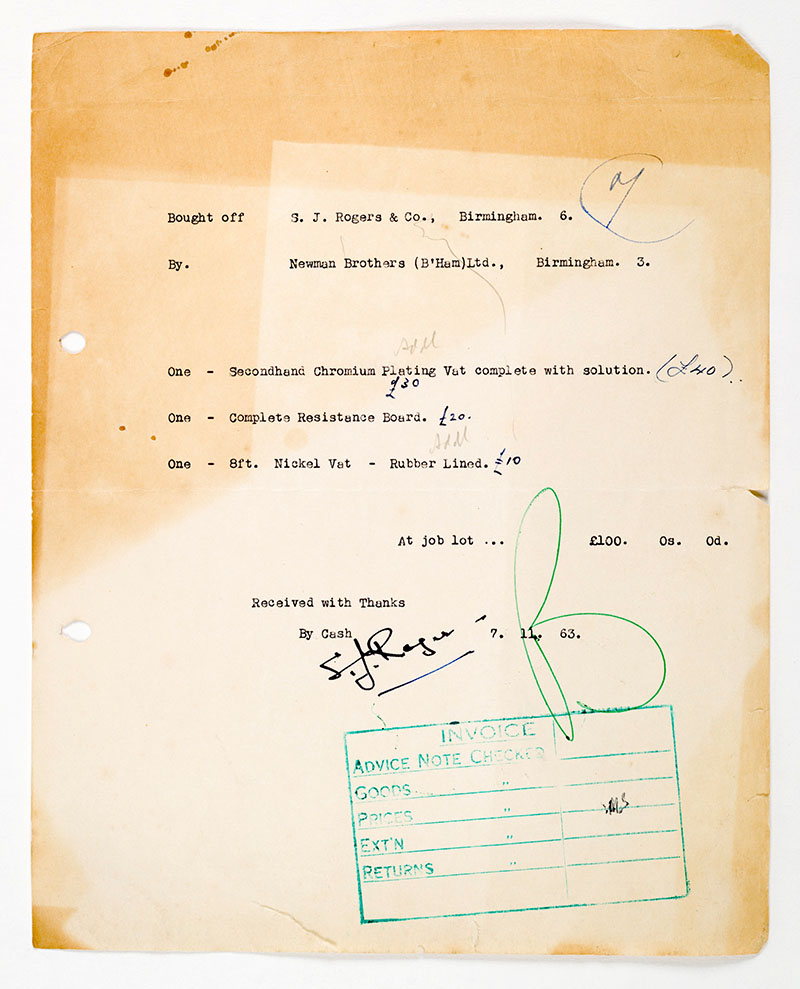

This document is the invoice for the purchase of a second-hand vacuum coating machine. This machine was used to apply metallic finishes to the plastic coffin furniture designed for use in cremations and was installed in 1963.

Newman Brothers adapted to the increasing popularity of cremations by creating plastic versions of their most popular coffin furniture designs. These were manufactured by an outside supplier and later coated at the factory by the vacuum coating machine, giving the furniture a metallic finish. Through the 1950s and 60s, it was the new directors like John Kellett and Charles Floyd, who took Newman Brothers forward and sought to adapt to changes in the funerary industry. The most important of these was the shift from inhumation to cremation.

At the end of the Second World War less than 10% of deaths were followed by cremation. By 1965 this figure had risen to 50%. In the 1960s, Birmingham City Council’s cremation regulations stated that “Coffin furniture and fittings must be of a combustible nature and the Corporation reserves the right to remove any brass or metal fittings.” This was not good for a company that specialised in metal fittings!

The factory range which had housed the casting shops and stables was demolished about 1967 and replaced with a modern two-storey range containing new offices and workshops. The company records show that a separate firm manufacturing coffins operated from the factory around this time. The new management aimed to make Newman Brothers a “complete unit” for the supply of coffins, coffin fittings, linings and funerary gowns – everything the funeral director could need.