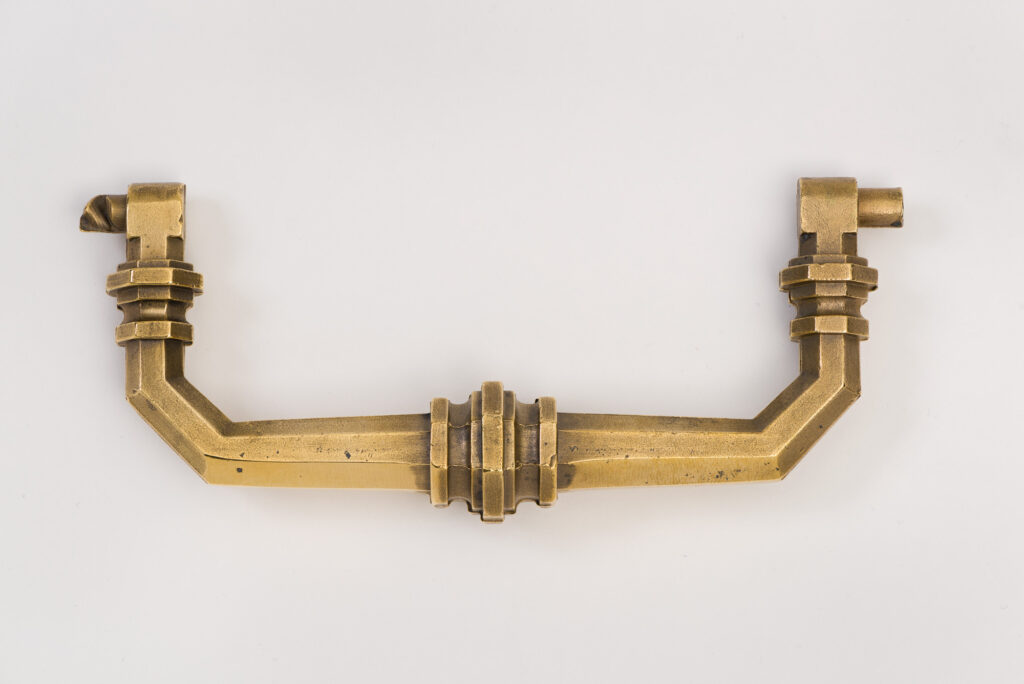

This brass handle was produced using the process of sand casting. This is a process in which liquid brass is poured into a mould which is a hollow cavity of the desired shape. In this case the shape is a gothic handle, the metal is then allowed to cool and solidify. That this handle is burnished means the brass has been smoothed-out with a fine burring element, in this a series of polishing mops were used on it.

Between 1894 and 1998 Newman Brothers variety of methods to produce their range of coffin furniture including stamping, casting and planishing. Their metal of choice was brass especially between 1882 to the 1930s. Other metals they used included zinc and aluminium, particularly from the 1960s onwards.

The main electroplated base on Newman Brothers’ products (the ‘finish’) was either ‘electro-brassed’ (known as EB) or nickel plate (NP). Many people have assumed that their nickel plated items were plated with silver, but there is no evidence to suggest Newman Brothers ever used either silver, or gold.

The one-storey range containing this workshop was demolished in 1967 and replaced by the two-storey range we see today.